Ibarmia

Your Machine Tool Point

Ibarmia Machines provide precision and are built as durable machines with the most advanced technology. Ibarmia machines provides the edge with:

- Total access to the work table

- Optimised crane access

- Automatic doors

- Ergonomic design

- Manual tool change

- Control Panel

A wide opening of the front doors allows an excellent access to the working table to load, unload and fix pieces. The design of the doors allows a wide opening of the roof*, allowing a crane access to load/unload heavy and/or voluminous pieces. *Optional in ZV CLASSIC.

No physical effort from the operator to open and close the doors. The system allows an independent closing/opening of each working area in pendulum cycle. *Optional.

The machine bed and guarding allow a space under the table where the operator can place his feet for an ergonomic access to the machine’s working area. Manual tool change or tool status check can be done from a very comfortable position; the distance to the change point is optimal. Ergonomic design of the control panel. The inclination and height of the different areas of the panel are designed for an optimum interaction with the operator. Moving control panel allows an easier interaction between machine and operator. The light control panel is very light thanks to the materials used (polyester reinforced with fibreglass), making it very easy to move.

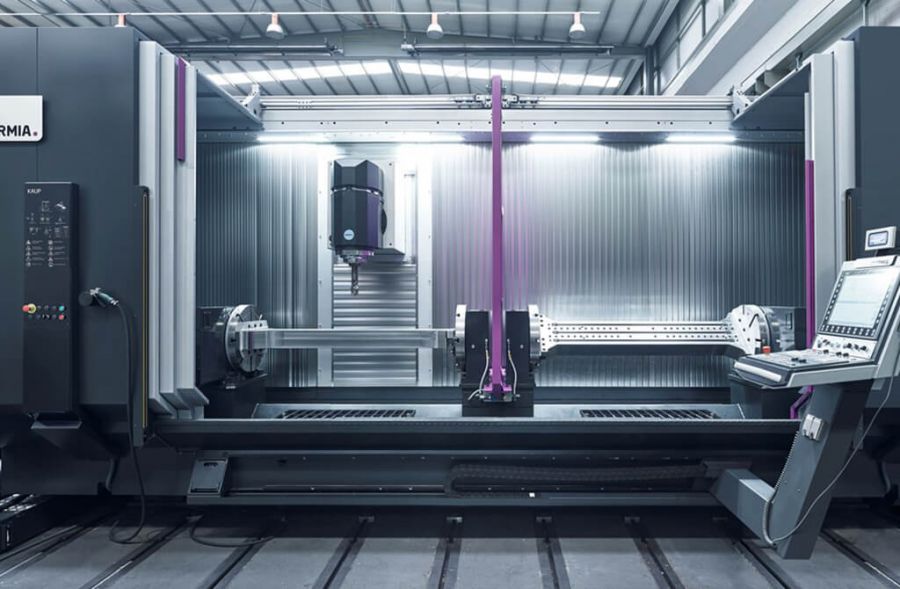

The Z-Series

Moving Column Machining Centres

The Most Flexible Machine Setup In The Market

Flexibility :

By flexibility we mean capacity to machine pieces in a wide range of sizes: small, medium, and large and from various industrial sectors such as general subcontracting, mould making, machinery making, energy sourcing, automotive and aerospace. The high configurability and the combination possibilities offered by the fixed working table provide an unlimited field of work, a differential value for the customer and a return of investment of maximum viability.

Ergonomics :

By ergonomics we mean full, immediate, comfortable access of the operator to the working table for loading/unloading operations or for control operations during the machining process. If we add a working area designed for easy swarf removal, an easy top access via bridge crane even in the fully enclosed versions, moving control panel with inclined screen and keyboard, wide vision of the working area, total separation of working areas in pendulum cycle… it is not a surprise that this is the favourite design for operators and qualified experts of the sector.

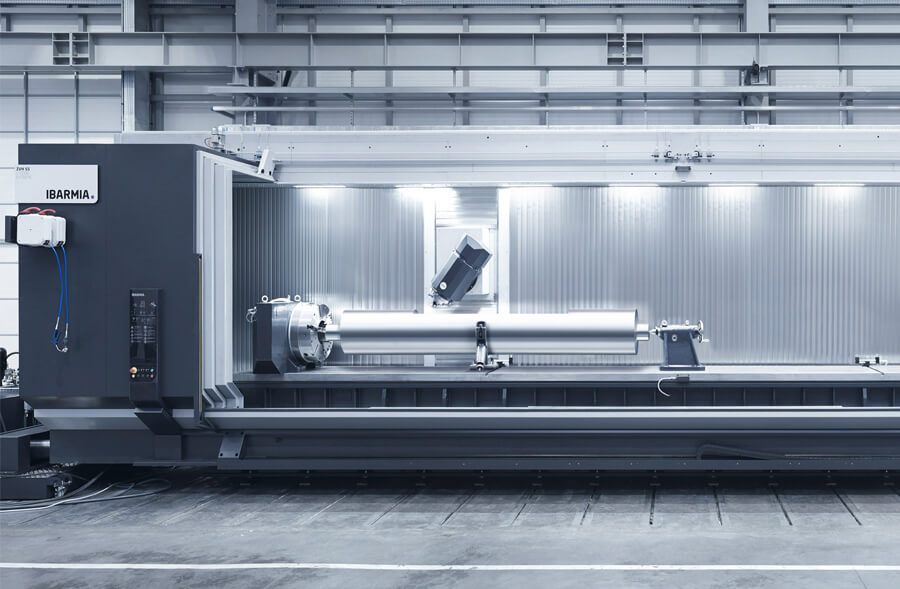

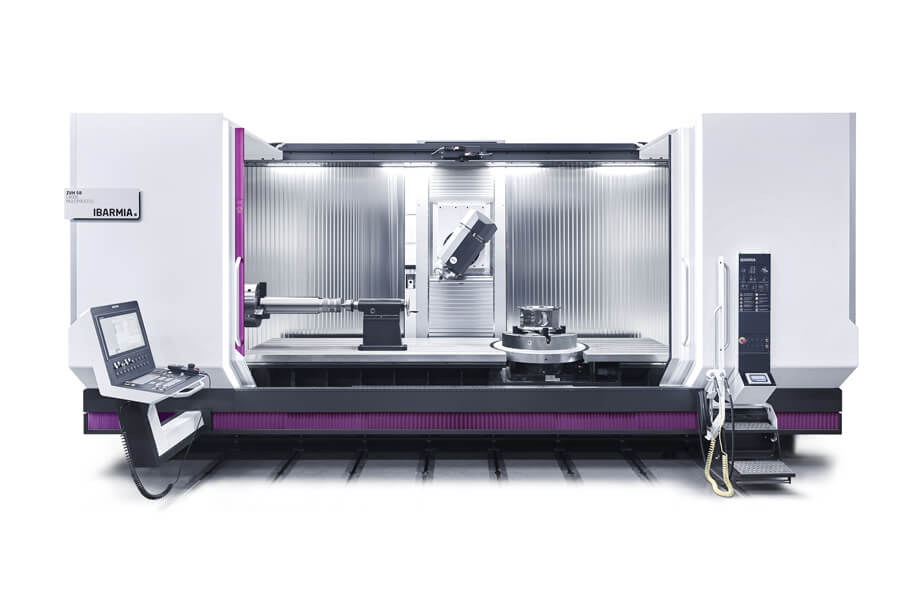

The Ibarmia ZVH Multiprocess

40/45/48/50/55/58/60

The integration of machining processes in the IBARMIA MULTIPROCESS Series minimizes the amount of machines required and reduces considerably the machining times of complex pieces.

But these are not the only advantages of applying the most advanced, groundbreaking and unstoppable technology of the last years, a technology that sets a milestone in the machining universe and clearly raises the bar of its users over their competitors.

The efficiency associated to the MULTIPROCESS centres improves the quality of the final piece as fewer machines and thus fewer piece set ups are required; it reduces the cost of the initial investment as well as the floor space required, eliminates the transit of pieces between machines and simplifies the production management.

Higher Productivity In Your Machining process,

More Competitive In The Market

Moving column with tilting head for milling and turning operations. The combination of the tilting head with milling and turning capacities, with 1 or 2 turning axes (horizontal or vertical turning axis) and the possibility of the use of pendulum cycles, make the ZVH MULTIPROCESS a bet for the highest technology and the maximum equipment display for the industry.

The integration of machining processes in the IBARMIA MULTIPROCESS Series minimizes the amount of machines required and reduces considerably the machining times of complex pieces. But these are not the only advantages of applying the most advanced, groundbreaking and unstoppable technology of the last years, a technology that sets a milestone in the machining universe and clearly raises the bar of its users over their competitors.

The efficiency associated to the MULTIPROCESS centres improves the quality of the final piece as fewer machines and thus fewer piece set ups are required; it reduces the cost of the initial investment as well as the floor space required, eliminates the transit of pieces between machines and simplifies the production management.

Integrated Vertical Turning Plates

High dynamics for turning operations and accurate positioning for milling operations. Wide range of turning speeds for vertical or horizontal turning operations.

Clamping Devices

Jaw chucks and clamping devices designed for milling and turning operations. Consulting and/or manufacturing clamping devices for pieces of our customers. Our proven track of 60 years building, most importantly, using machines, back us.

Flexibility With No Limits

Various works on the turning plate or the fixed table, with the possibility of combining them with the pendulum configuration. We give you the means and support using them. Maximize your performance.

HSK A-100

Tool holding force and maximum rigidity for milling and turning tools. Please check for other tool holding systems (KM, Capto, HSK-T…)

New Machining Concept

Head tilting range +/- 105º with motor spindle of 12.000 rpm for milling and turning with a blocking system for the tool. Precise assembling by expert hands in a room with constant temperature. IBARMIA’s own design developed by static and dynamic analysis of the behaviour under efforts in milling and turning operations.

B-Axis of High Dynamics

The multiprocess concept reduces time and errors, drastically increasing the productivity. Combination of the following processes in one single machine: milling, drilling, tapping, boring, turn/mill and turning. Multiple configurations of vertical and horizontal turning axes from Ø250 mm to Ø2000 mm.